| Sign In | Join Free | My gimpguru.org |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gimpguru.org |

|

Brand Name : ZK

Model Number : Oil Fracturing Proppant Production Line

Certification : CE ISO Certification

Place of Origin : China

MOQ : 1 Set

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10 Set / Sets per Month

Delivery Time : 30 days

Packaging Details : Export standard container or as customers' requirements

Product Name : Oil Fracturing Proppant Rotary Kiln production line

Condition : New

After-sales Service Provided : Engineers available to service machinery overseas

Warranty : 12 Months

Color : As client's request

Application : Oil Fracturing Proppant production

Main Materials : Bauxite

Capacity : 10000-30000(t/a)

Main Equipment : Ball Mill,Oil fracturing proppant Kiln,Granulator

Port : Qingdao,shanghai,tianjin

Oil Fracturing Proppant Rotary Kiln production line with 0.8-105(t/h)

BRIEF INTRODUCTION

We are leading manufacturer of complete equipment for Fracturing Proppants Production Line. We can provide the whole service of design, equipment/spare parts supply, investment consultation, installation and operation training for Fracturing Proppants Production Plant. We have done many successful projects in both China and overseas countries.

We also produce different specifications of ceramic proppant. Ceramic sand (Oil Proppant) is a kind of products of ceramic particle, which has a high fracturing intensity, mainly used for oilfield as downhole proppant, the usage is to increase the output of oil and gas. So ceramic sand is a kind of green and environmental protection products. Ceramic sand (Oil Proppant) made of high quality bauxite and other additive material, granulating and calcining to increase the strength and density. It’s a substitute of natural quartz sand, glass sand, metallic sand and other low intensity proppant. Ceramic sand is the best proppant to increasing oil and natural gas output.

OUR ADVANTAGE

1. Saving energy

The refractory lining of the rotary kiln consists of the outer insulation made of light refractory brick and inner compound refractory bricks. Such kind of lining will reduce the heat emission on the shell surface of the rotary kiln as much as possible. The pre-heater at the end of the rotary kiln will recycle the heat to preheat the material and save fuel by 40% and increase the output by 30%.

2. Low consumption

Rotary cooler at the discharge end of rotary kiln recycles the heat of Oil fracturing proppant which is discharged from the rotary kiln, and will preheat the secondary air up to 500℃.

3. Environmental protection

Two phases of dust collection including cyclone filter and bag filter, will control the dust emission below the limitation of the national standard.

4. High degree of automation

PLC control system improve the job efficiency.

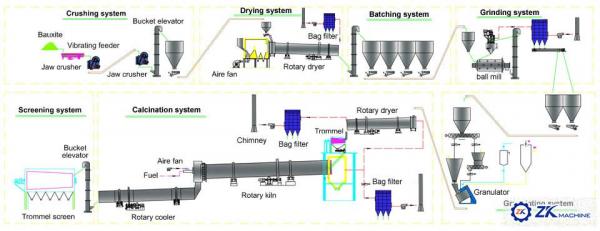

PRODUCTION TECHNOLOGY

Bauxite will be firstly crushed by jaw crusher and hammer crusher and then it will be conveyed to batching silo.

After batching with other material, materials will be sent to ball mill and grinded into powder. Classifier will be used after ball mill for size grading. Here raw material will be sent to silo again.

Then raw material will go to granulator and will be made into different size pellets. Pellets will be sent to screening equipment. Qualified size pellets will be conveyed to rotary kiln for calcination. Oversize pellets will be sent back for grinding.

After pellets calcined in rotary kiln, we get qualified product ceramic sand. At last, ceramic will go to cooler for cooling. And will go to screen to get different size oil fracturing proppant and will be packed in ton bag. The production process ends.

PRODUCTION PROCESS

|

|

Oil Fracturing Proppant Rotary Kiln Production Line 0.8-105 T/H Convenient Maintenance Images |